To guarantee the highest purity and efficacy, we adhere to strict global standards

To guarantee the highest purity and efficacy, we adhere to strict global standards

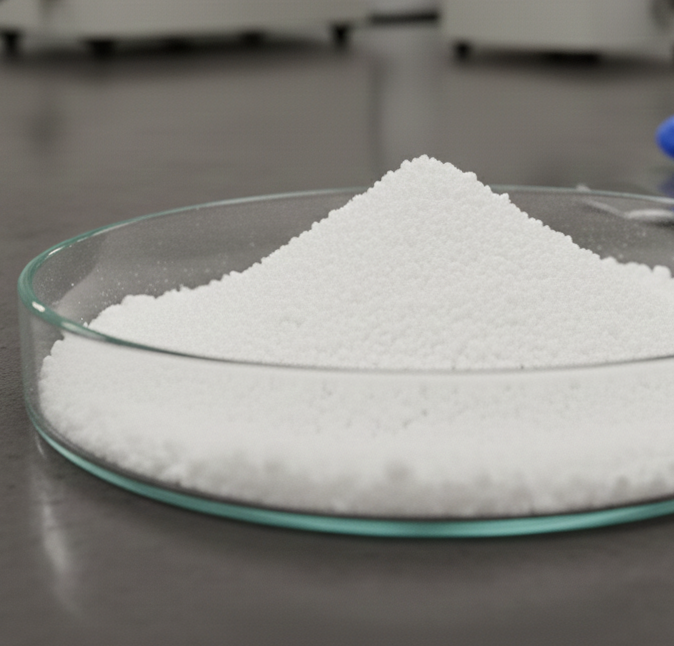

Polyvinylpyrrolidone (PVP) is a synthetic, water-soluble pharmaceutical excipient characterized by its excellent biocompatibility and strong film-forming properties. PVP is a multifunctional excipient, primarily used as a Binder in tablets, a Dispersant and Stabilizer for Solid Dispersions, and a carrier for APIs with poor aqueous solubility. The different grades (such as K30 and K90) are defined by their K-value, which relates to their average molecular weight and viscosity.

40,000 - 55,000 Daltons

Standard Binder for wet granulation, and a solid dispersion agent via spray drying.

1,000,000 - 1,500,000 Daltons

Very Strong Binder for wet granulation (at lower concentrations), and a film former for dermal or mucoadhesive patches.

Lower Molecular Weight

Solid solutions, and tablet sugar coating.

The product fully complies with the requirements specified in the United States Pharmacopeia (USP), the European Pharmacopoeia (EP), and/or other relevant standards.

Strict control over the K-value and viscosity (in a standard aqueous solution) is maintained to ensure consistent binding strength in tablets.

Control over monomer content (NVP), water, and moisture.

Production is conducted in a rigorous cGMP environment, ensuring consistency in physicochemical properties.